从传统的角度来看,大多数雇主都会看到工业卫生项目作为其工人暴露的前端评估。这通常作为“桌面”的操作审查,然后开发成曝光评估或采样计划,然后使用来自个人监视器和/或区域监视器的数据来导致实际的曝光评估。

However, much of the time the evaluation and interpretation of the workplace sampling results is not the final step. If the results indicate that your workers’ exposures are below the applicable Occupational Exposure Limits (OELs), such as the Occupational Safety and Health Administration’s (OSHA) Permissible Exposure Limits (PELs), the American Conference of Governmental Industrial Hygienists (ACGIH) Threshold Limit Values (TLVs), or the National Institute of Occupational Safety And Health (NIOSH) Recommended Exposure Levels (RELs) then it is assumed your workers are not being exposed to harmful or dangerous levels of chemicals while at work. However, if the data indicates an exceedance of an OEL, then the next step is to reduce the exposure.

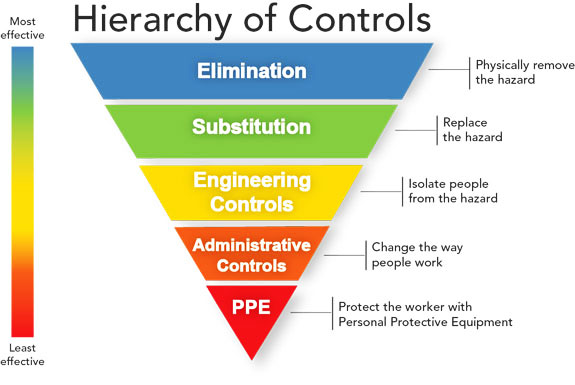

The graphic above shows the Hierarchy of Controls, well known in the safety and health field of work. As you look at it from top to bottom, the effectiveness of the control is reduced. Obviously, the elimination of the process or hazardous chemical (or hazardous noise level) would be the best way to eliminate or minimize the exposure, but sometimes it is not feasible due to quality requirements, product design, military specifications, or customer specifications.

If you can’t eliminate the hazard, then the feasibility of engineering controls should be considered next. Engineering controls are integrated into the process so that employees can perform the task safely and exposure is minimized. Engineering controls are often the sweet spot, or the middle bowl of porridge, when you consider costs versus effectiveness of the control. Additionally, engineering controls reduce the potential for exposure while reducing the responsibilities of the employee (i.e., correctly following a safe work procedure or properly wearing protective equipment).

根据您的情况,工程控制可以像安装过程中的局部排气一样简单。但需要什么样的?如果您调查桌子,通风橱,空气单元集成到单位本身的吸尘器?所有这些都是可行的选项,但是一个方法可以根据应用程序做出更多意义。也许你只需要增加该地区的通风。您推出的户外空气越多,您推出的“受污染的”空气,潜在的曝光率就越低。

例如,从需求ents of OSHA’s silica standard, we are seeing more and more engineering controls become available that are designed to reduce employee’s exposure to respirable silica during routine tasks such as those involving concrete in construction. Many companies have begun using integrated vacuum units around smaller units that extract the concrete dust particles as they are being generated. Some are using hoses that apply water to the concrete as you cut, minimizing the potential for respirable dust. Whatever the application is, we can help identify a control or set of controls for your process. Many times, just one control is not enough to limit all the hazards for a process. You will have to consider all the hazards: chemical exposures, pinch points, electrical hazards, etc., that may require controls.

如果工程控件是不可行的,则在层次结构中,管理控件将在待考虑的层次结构中进行。管理控制侧重于更改员工如何执行工作或任务。例如,任何时间任务XYZ都执行,员工必须遵循旨在限制曝光的安全工作实践。另一种类型的曝光控制可以是人员的旋转,所以一个员工整天没有执行任务。考虑的最终控制是使用个人防护设备(PPE)。PPE在控制曝光时有效,但它不会消除或减少危险 - 仍存在。员工暴露的减少将受到PPE的适当(或不当)选择和佩戴的影响。PPE最初可以看起来相对便宜,但如果您考虑随时间更换PPE的每位员工的重复成本,而员工培训,则可能相当昂贵。行政控制和PPE的使用都将一些责任放在员工上。如果他们忘记否则他们不适合,或者他们忘记了行政控制,那么曝光的可能性仍然非常真实。

For any questions regarding worker exposures or industrial hygiene in your facility, please give us a call or click the link below to fill out our Contact Us form.